Marine Applications

We design cylinders for all types of marine environments including those experienced in applications for vessels such as;

- Naval vessels.

- Offshore rigs and support vessels.

- Subsea vessels.

- Passenger vessels such as Ocean Liners and Fast Ferries.

- Commercial vessels such as Bulk Carriers, Car Carriers and Tankers.

- Ship Mounted or Dockside Cranes.

- Megayachts and other luxury vessels.

We also specialise in the design and manufacture of ultra-high strength cylinders for applications such as Ride Control Systems. These designs take into account the extreme slam load induced pressures encountered when ride fins momentarily exit and then re-enter the water under extreme seastate conditions.

These pressures can be well over 10,000 PSI so various high strength steels and stainless steels with great tensile and impact strength are used. These materials, combined with a focus on engineering and safety, result in Ride Control cylinders that are superior and used on some of the world’s most advanced and fastest Naval Vessels.

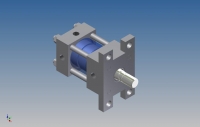

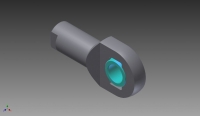

Marine Hydraulic Cylinders in Action

The marine environment is by far the most arduous for hydraulic equipment with many and varied conditions that combine to increase the likelihood of premature failure.

It is very important therefore to design hydraulic cylinders with these particular environmental conditions very much in mind, if they are to perform at or above expectations.

Corrosion is the largest single contributor to premature failure and we therefore take many precautions during design and manufacture to ensure cylinder life is not compromised.

Common Applications

- Steering and Rudder Control

- Ride Fins

- Hoistable Decks & Ramps

- Cranes & Davits

- Bow & Stern Doors

- Personnel Lifts

- Goods Lifts

- Ammunition Lifts

- Clam Shell Systems

- Watertight Systems

- Deck Hatches

- Locking Dogs

- Heave Compensators, active & passive

- Riser Tensioners

- Mooring Tensioners