Capabilities & Capacities

Being the sole Australian holder of our Germanischer Lloyd and ABS cylinder approval makes us one of the most qualified marine cylinder manufacturers in Australia.

Common Applications

- Steering and Rudder Control

- Ride Fins

- Hoistable Decks & Ramps

- Cranes & Davits

- Bow & Stern Doors

- Personnel Lifts

- Goods Lifts

- Ammunition Lifts

- Clam Shell Systems

- Watertight Systems

- Deck Hatches

- Locking Dogs

- Heave Compensators, active & passive

- Tensioner Systems

- Mooring Systems

Accreditation

Ezy-Fit Hydraulics’ commitment to producing a quality product using best practice production methods has enabled us to secure several highly regarded accreditations.

|

Germanischer Lloyd Approval for Welding of Machinery Components - Hydraulic Cylinders |

|

Quality Assurance Certification ISO 9001.2008 ISO 9001 Certificate No FS 603786 | View Certificate |

|

Type Approval Certificate 11-HS798178-PDA | View Certificate |

|

DNV Welding Certificate 11903138-1 and 11903138-2 for welding of Duplex and Super Duplex stainless steels. | View certificate |

|

Type Approval Certificate Manufacturing Assessment - MQ2090862 | View Certificate |

As well as being the sole Australian holder of the Germanischer Lloyd welding shop approval, we have American Bureau of Shipping Type Approval on several designs of heavy duty Ride Control System actuators, and recently successfully completed our Manufacturing Assessment Certification. We have also previously worked on many occasions with other global marine classification societies such as Det Norske Veritas and Lloyds Register of Shipping, having many cylinder designs and welding procedures approved, making us arguably the most qualified marine cylinder manufacturer in Australia.

If you require any further information on our Company or how we can service your hydraulic cylinder needs, please feel free to contact us.

Capability

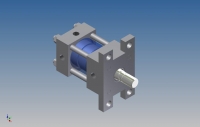

Ezy-Fit Marine has modern state of the art facilities which include CAD/CAM design and production technology for accuracy of drawings, components and finished product.

We use the latest in CNC lathes and machine centres, saws and honing equipment. Our engine lathes allow us to machine up to 12 metres in length with up to a 1250mm swing.

We are highly capable in the welding of ferrous and stainless steels for which we have certified procedures and personnel, and have MIG, TIG and Oxy-Acetylene equipment.

All welds are non-destructive tested to varying degrees depending on the class requirements.

Factory Equipment

Our factory’s facilities include the following equipment:

- CAD equipped design office

- Six centre lathes with up to 12 metre bed and 1250mm swing

- Twelve CNC lathes

- Three bar feeders

- Seven CNC machine centres with up to 5 axis control

- Sunnen HTS-074-075 tube hone with capability of up to 900mm bore and 15 metre stroke length

- Sunnen HL3500 tube hone with capability up to 16" bore and 7 metre stroke length

- Four welding bays with the latest in MIG and TIG welding equipment

- One robot welder

- One manual mill

- One radial drill

- Four CNC sawlines

- Six assembly stations

- Four mineral oil and one ethylene glycol pressure test units up to 690 bar

- Torque multiplier up to 1559 Nm

- Various overhead cranes, gantry cranes and forklifts

- Paint shop

Positioning Sensors

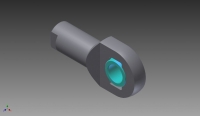

We are able to fit positioning sensors to most cylinders, including internal and externally mounted profile type Linear Displacement Transducers. Stroke range is 10mm to in excess of 6000mm.

Valving

We can custom design various types of valving requirements to complement your cylinder design and circuit requirements. All valve blocks are manufactured in house to exacting standards on CAD/CAM multi-axis machine centres and many different cavity tools exist in our store to suit your valve cartridge brand and flow rate needs.

Valve blocks can be remote mounted and hard piped or welded directly to the cylinder or piston rod end. In-line end cap mounted and piggy-back mounted, among other mounting styles, can be achieved. Welding the valve block directly to the barrel rather than remote mounting eliminates potential leak points, and enhances the strength and reliability of the cylinder. All tube lines can be permanently welded or fitted with removable threaded connections for ease of service work.

Cushioning

Cushions of several types can be designed into suitable cylinders and include fixed and adjustable, spear type, piccollo and occluded port type.